5 Important Considerations When Acquiring Automatic Labeling Equipment

As your business grows, the ability to swiftly and properly label your products as they come out of the production line becomes an even more important consideration. After all, the label or packaging is the “face” that will tell your customers what your product is all about. The labels will also contain vital information about your products, whether it’s the nutritional value of a food item, the volume content of a liquid product in a container, or personalized details regarding a prescription drug.

As such, it is also critical for you to pick the right automation solution that will suit your labeling and packaging needs down to a tee. If you’ve been wondering about what the most important considerations are when shopping for the best labeling and packing equipment,you’ve come to the right place. Read on to learn more about these.

Adjustability and Adaptability

While it might not be possible to have just one single labeling or packaging machine for all of your products, it‘s always best to choose an equipment that allows you to adjust the labeling configurations depending on the nature of the products that you are going to feed into it. This is especially important for businesses that manufacture or distribute a variety of products.

For example, a labeling machine that can apply labels and packaging on containers of different shapes and sizes is definitely better than one that can only place labels on cuboid containers. A machine that can handle both sticker-type labels and shrink wraps is also better than a machine that can only work with one of these.

Accuracy and Precision

If you’re going to be maintaining an efficient labeling and packaging operations, you need equipment that can perform accurate and precise label applications with consistency, no matter how many items are fed into the machine.

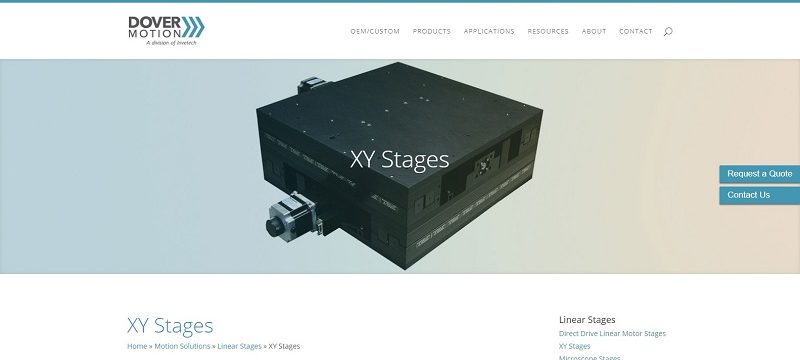

For this purpose, you should get a machine with smart sensing controls and precision motion components that will remain reliable no matter the volume of throughput you require. For example, a labeling machine with highly precise XY linear stages will be able to apply labels with an accuracy of within just a few microns.

Speed for High-Throughput Applications

Smaller business can probably get by with labeling and packaging equipment that are quite slow and are basically designed for low-throughout applications. However, bigger businesses need labeling systems that can deliver the speed and reliability needed in a high-throughput environment. By choosing the latter, you’ll be able to create labels at a much shorter period of time, allowing you to better meet customer demands as they grow.

Robust and Reliable Construction

Labeling and packaging are often very demanding processes. As such, you wouldn’t want an equipment that can easily break down after just a few months’ use. Your machines need to be well constructed, durable, corrosion-resistant, relatively maintenance free, and built to last. This way, you’ll be getting the most out of a potentially costly investment.

Easy Operability

Lastly, a labeling and packaging machine should also be easy to operate and control. Choosing equipment that require just a shallow learning curve is helpful if you want to ensure safe and convenient operation on your production floor. If possible, purchase only equipment whose manufacturers can offer proper training and on boarding for your workers. You wouldn’t want to buy a machine that only comes with a vague guide booklet.

Automating your product labeling process is an important step towards achieving economies of scale and becoming a more efficient business. Just make sure that you’re also choosing the right equipment to accompany you in your journey.

Subscribe & Get E-Mail Updates Delivered

Our informative Design related articles featuring the latest Resources for Web Designers & the Web get delivered via email dialy. Thousands of readers have signed up already. Why don't you subscribe as well, and get articles delivered to your inbox?

Leave a Reply